5 Axis CNC Machining Services

Widely used in the automotive, aerospace, robotics, medical and other industries, 5-axis CNC machining services are an effective way to rapid manufacturing complex metal or plastic parts. Welcome to contact our engineering experts for further communication.

Category:

Service

key word:

5 Axis CNC Machining Services

Service Introduction

5 Axis CNC Machining Services

Widely used in the automotive, aerospace, robotics, medical and other industries, 5-axis CNC machining services are an effective way to rapid manufacturing complex metal or plastic parts. Welcome to contact our engineering experts for further communication.

ISO 9001:2015 Certified.

More than 160 Certified Materials

Tolerances Up to ± 0.005mm

100% Quality Guaranteed.

Global Delivery

High Precision, Higher Quality 5 Axis CNC Machining Services

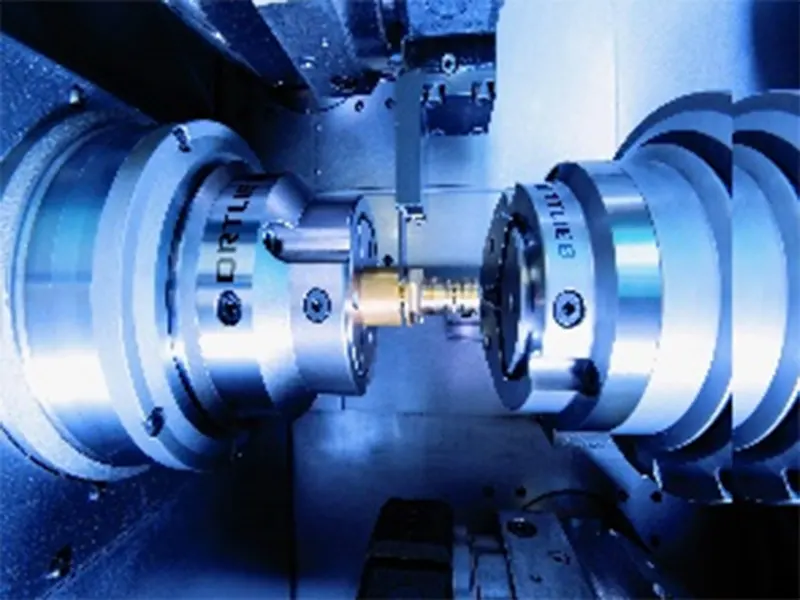

The possibilities of 5-axis CNC machining services are essentially limitless, unique in their ability to efficiently machine your metal or plastic parts. Guangzhi precision invests in state-of-the-art five-axis CNC machining equipment and experienced machinists to machine parts with extremely complex geometries with high precision.

5 Axis CNC Machining Capabilities

For complex, time-critical custom parts, 5-axis CNC machines offer unrivaled flexibility and speed. GZ Precision have experienced team and can help bring your designs to life, from rapid prototyping to final parts for high-volume manufacturing. For information on our general CNC machining services, including 3-axis, 4-axis milling, CNC turning and EDM, see our CNC machining services page.

Advantages of 5 Axis CNC Machining

GZ Precision 5-axis machining services can exceed your expectations. The advantages of working with us include:

1.Quick Turnaround

With 10 sets of in-house 5-axis machines, we have the ability to manufacture your prototypes and low-volume manufacturing within 1-5 days.

2.Top-Quality 5-axis Machines

HAAS , DMG and Jingdiao 5-axis CNC machines from the USA,Germany with on-site inspection systems for ultra-tight tolerances.

3.Experience and Expertise

With 15+ years in the CNC machining business and a thorough understanding of material properties, we know how to handle the most complex parts ,no matter the material.

4.Industry Compatibility

From aerospace parts to high-tech electronics, customers in more than 30 countries around the world in various manufacturing fields have established partnerships with us.

What is 5-axis CNC Machining

The cutting tool on a 5-axis CNC machining center can move along five axes instead of the usual three. Compared to a 3-axis CNC machine where the spindle can move up and down, side to side, and back and forth, a 5-axis machine has two other axes at work: the table swings from side to side on two different axes, or the spindle itself rotate on an axis. This allows the cutting tool to approach the work piece from an infinite number of angles, remove excess material, and create parts with highly complex shapes.

axis CNC machining reduces the number of setups required: Machinists don’t have to manually flip the work piece because cutting tools can simply reach more positions. This makes the entire machining process very fast.

5 Axis CNC Machining Services

Widely used in the automotive, aerospace, robotics, medical and other industries, 5-axis CNC machining services are an effective way to rapid manufacturing complex metal or plastic parts. Welcome to contact our engineering experts for further communication.

ISO 9001:2015 Certified.

More than 160 Certified Materials

Tolerances Up to ± 0.005mm

100% Quality Guaranteed.

Global Delivery

High Precision, Higher Quality 5 Axis CNC Machining Services

The possibilities of 5-axis CNC machining services are essentially limitless, unique in their ability to efficiently machine your metal or plastic parts. Guangzhi precision invests in state-of-the-art five-axis CNC machining equipment and experienced machinists to machine parts with extremely complex geometries with high precision.

5 Axis CNC Machining Capabilities

For complex, time-critical custom parts, 5-axis CNC machines offer unrivaled flexibility and speed. GZ Precision have experienced team and can help bring your designs to life, from rapid prototyping to final parts for high-volume manufacturing. For information on our general CNC machining services, including 3-axis, 4-axis milling, CNC turning and EDM, see our CNC machining services page.

Advantages of 5 Axis CNC Machining

GZ Precision 5-axis machining services can exceed your expectations. The advantages of working with us include:

1.Quick Turnaround

With 10 sets of in-house 5-axis machines, we have the ability to manufacture your prototypes and low-volume manufacturing within 1-5 days.

2.Top-Quality 5-axis Machines

HAAS , DMG and Jingdiao 5-axis CNC machines from the USA,Germany with on-site inspection systems for ultra-tight tolerances.

3.Experience and Expertise

With 15+ years in the CNC machining business and a thorough understanding of material properties, we know how to handle the most complex parts ,no matter the material.

4.Industry Compatibility

From aerospace parts to high-tech electronics, customers in more than 30 countries around the world in various manufacturing fields have established partnerships with us.

What is 5-axis CNC Machining

The cutting tool on a 5-axis CNC machining center can move along five axes instead of the usual three. Compared to a 3-axis CNC machine where the spindle can move up and down, side to side, and back and forth, a 5-axis machine has two other axes at work: the table swings from side to side on two different axes, or the spindle itself rotate on an axis. This allows the cutting tool to approach the work piece from an infinite number of angles, remove excess material, and create parts with highly complex shapes.

axis CNC machining reduces the number of setups required: Machinists don’t have to manually flip the work piece because cutting tools can simply reach more positions. This makes the entire machining process very fast.

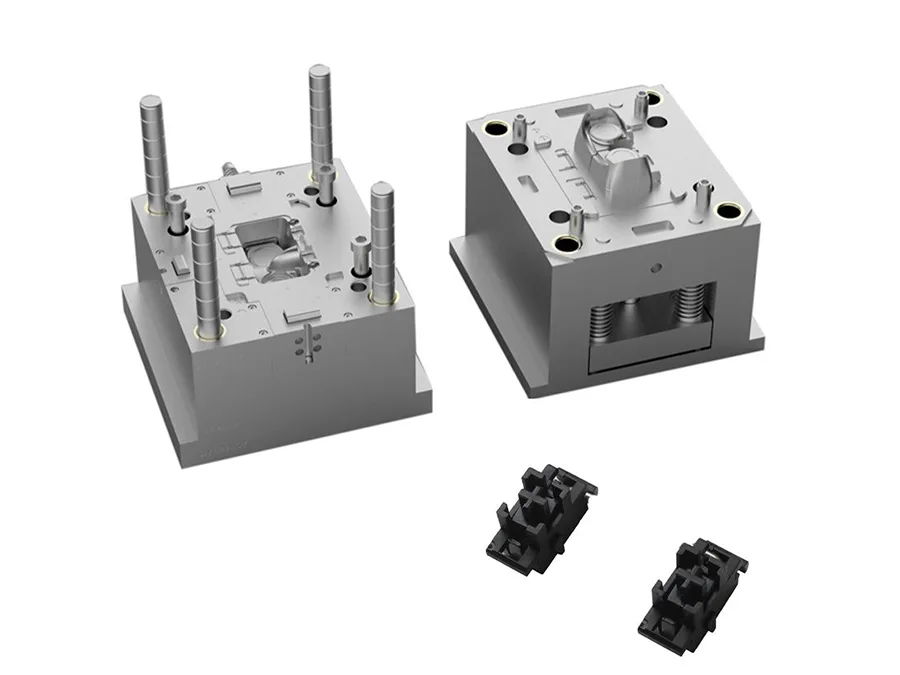

Application Industry Guide to 5-Axis CNC Milling

To manufacture complex, high-precision parts, 5-axis CNC milling service is your best choice. Our manufacturing capabilities allow us to quickly manufacture a wide variety of components, including:

Automotive parts: engine housings, light guides, valves, engine covers, inspection fixtures.

Aerospace parts: fuselage sections, bulkheads, landing gear components.

Medical and surgical tools: tweezers, scalpels, spacers, clips, cutters, surgical scissors.

Military components: submarine components, turbine blades, engine components, weapons, sensors.

To manufacture complex, high-precision parts, 5-axis CNC milling service is your best choice. Our manufacturing capabilities allow us to quickly manufacture a wide variety of components, including:

Automotive parts: engine housings, light guides, valves, engine covers, inspection fixtures.

Aerospace parts: fuselage sections, bulkheads, landing gear components.

Medical and surgical tools: tweezers, scalpels, spacers, clips, cutters, surgical scissors.

Military components: submarine components, turbine blades, engine components, weapons, sensors.

FAQ

What’s the main difference between 3+2 Axis and 5-axis CNC machining?

3+2 axis CNC machining adds positioning without simultaneous movement, while 5-axis enables simultaneous movement in five directions for complex and precise parts.

Which is more precise between, 3+2 Axis vs. 5-axis CNC machining?

5-axis CNC machining is typically more precise than 3+2 axis machining, allowing for simultaneous movement in multiple directions enabling intricate and highly accurate part fabrication.

Why choose 5-axis CNC machining for complex designs?

5-axis CNC machining is chosen for complex designs due to its ability to precisely create intricate geometries, contours, and features without manual repositioning. It is ideal for industries with high precision demands.

How does 3+2 axis flexibility compare to the 5-axis?

3+2-axis machining offers angled flexibility but lacks simultaneous movement, whereas 5-axis machining provides continuous movement, enhancing flexibility for intricate part manufacturing.

Company Strength

Related service

Inquire Now

Note:We will contact you within one working day. Please pay attention to your email.