3d printing

3D printing technology has applications in aerospace, medical, automotive, military, mechanical equipment, electronics, consumer, artificial intelligence and other fields.

Category:

Service

key word:

3d printing

Service Introduction

What is 3D printing

3D printing, also known as additive manufacturing, is a technology that uses powdered metal or plastic and other bondable materials to construct objects based on digital model files by printing layer by layer.

It is basically the same as ordinary printing. The printer contains liquid or powder and other "printing materials". After connecting to the computer, the "printing materials" are superimposed layer by layer through computer control, and finally the design on the computer is turned into a real object. .

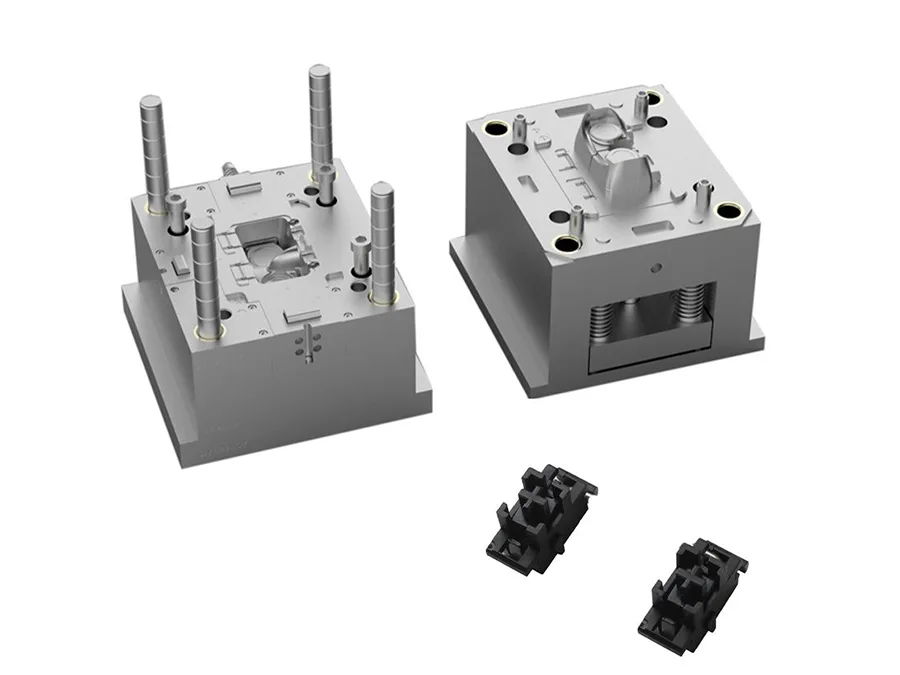

3D printing is often used in mold manufacturing, industrial design and other fields to make models, and then gradually used in the direct manufacturing of some products. Especially for production orders with many varieties and small batches, the cost-effective advantage is very obvious.

The technology has applications in aerospace, medical, automotive, military, mechanical equipment, electronics, consumer, artificial intelligence and other fields.

Light curing molding technology-SLA

Light-curing molding technology (SLA) mainly uses photosensitive resin as raw material, and utilizes the characteristic that liquid photosensitive resin will quickly cure under ultraviolet laser beam irradiation.

SLA focuses on the surface of the photocurable material by using ultraviolet light of a specific wavelength and intensity,

and solidifies it sequentially from point to line and line to surface, thereby completing the drawing of a layered cross-section.

Advantages of SLA process:

01. SLA can produce parts with high dimensional accuracy and complex details.

02. SLA parts have a very smooth surface finish, making it ideal for visual prototypes.

03. Special SLA materials can be used, such as transparent, flexible and castable resin.

Selective Laser Sintering-SLS

Selective laser sintering (SLS) belongs to the powder bed fusion process series, which can produce high-precision and durable parts, which can be directly used for end-use, small batch production or prototype prototypes.

Advantages of SLS process:

01. SLS parts have good isotropic mechanical properties, making them ideal for functional parts and prototypes.

02.SLS does not require any support and can easily produce designs with complex geometric shapes.

03. The manufacturing capacity of SLS is very suitable for small and medium batch production.

FAQ

Can I order just one piece?

Yes, of course you can, there is no minimum quantity with GZ Prototyping, we will recommend you with the most suitable and effective manufacturing solutions based on your quantities.

Does GZ-precision insure delivered goods?

No, we do not insure deliveries. However, you are free to use your own insurance.

When should I choose Vacuum Casting Services?

Vacuum casting is a method for making high quality prototypes or low volumes of parts formed from inexpensive silicone molds. Copies made in this way show great surface detail and fidelity to the original pattern.

When should I choose 3D printing Services?

We can use diverse 3D printing processes to fabricate your parts. More rapid and cost-effective compared with CNC Machining from one piece to large quantities.

3D printing has become a standard technique for developing one-off visual prototypes due to its speed, affordability, and flexibility. Printed parts sometimes lack strength and impact resistance, but this matters little for visual prototypes.

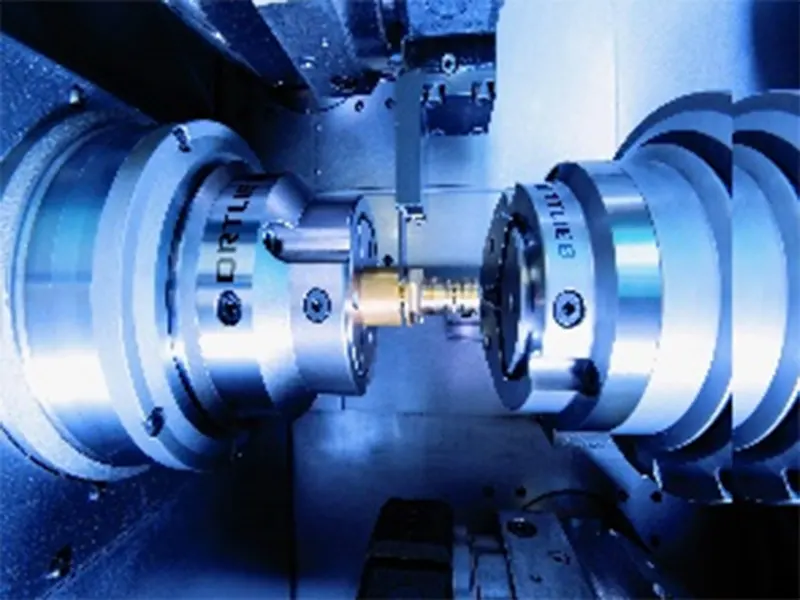

When should I choose CNC Machining Services?

Machined parts have the true properties of the material you select. Our process allows you to get parts machined from blocks of solid plastic and metal in the same time frame.

We mill and turn low quantities of parts very quickly. Typical quantities are one to 200 pieces and manufacturing times are 1 to 3 business days. We offer product developers parts machined from engineering-grade materials that are suitable for functional testing or end-use applications.

CNC machining is more expensive than plastic 3D printing, but it is the most feasible option for metal visual prototypes given the high cost of metal 3D printing and metal casting.

Company Strength

Related service

Inquire Now

Note:We will contact you within one working day. Please pay attention to your email.