sheet metal

Laser cutting technology allows us to produce processed parts at the fastest and best cost, while maintaining the highest quality standards. Sheet metal manufacturing is the process of turning flat metal plates into parts and structures of various shapes.

Category:

Sheet metal

key word:

Service Introduction

Sheet Metal

We provide metal cutting and bending services for the manufacture of sheet metal parts。

The automated cutting process guarantees the high precision and quality of the parts. All parts can be post-treated according to your requirements: coating, heat treatment and others.

Laser cutting

Laser cutting technology allows us to produce processed parts at the fastest and best cost, while maintaining the highest quality standards.

Sheet metal manufacturing is the process of turning flat metal plates into parts and structures of various shapes.

Bend

Customized sheet metal brake (forming/bending) service laser cutting parts, providing precise bending results plus superior repeatability.

Sheet metal processing is the process of processing a piece of metal into a desired shape by bending, stretching, and removing material.

The bending process results in a v-shaped, u-shaped, or channel-shaped shaft, creating a new part geometry.

The typical sheet metal parts we produce include enclosures, brackets, components, weldments, cabinets and other parts.

FAQ

Can I order just one piece?

Yes, of course you can, there is no minimum quantity with GZ Prototyping, we will recommend you with the most suitable and effective manufacturing solutions based on your quantities.

Does GZ-precision insure delivered goods?

No, we do not insure deliveries. However, you are free to use your own insurance.

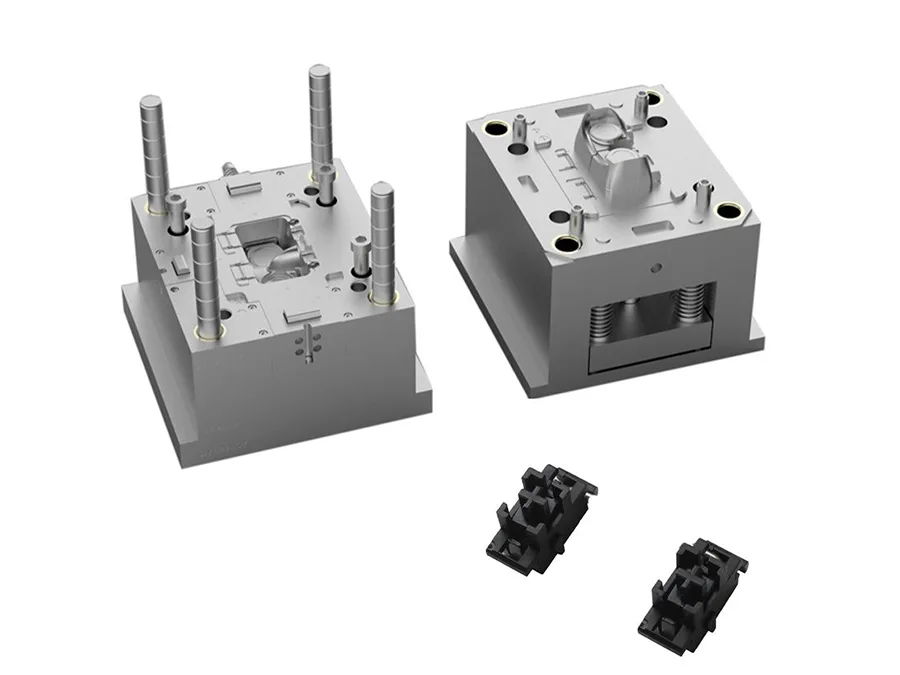

When should I choose Vacuum Casting Services?

Vacuum casting is a method for making high quality prototypes or low volumes of parts formed from inexpensive silicone molds. Copies made in this way show great surface detail and fidelity to the original pattern.

When should I choose 3D printing Services?

We can use diverse 3D printing processes to fabricate your parts. More rapid and cost-effective compared with CNC Machining from one piece to large quantities.

3D printing has become a standard technique for developing one-off visual prototypes due to its speed, affordability, and flexibility. Printed parts sometimes lack strength and impact resistance, but this matters little for visual prototypes.

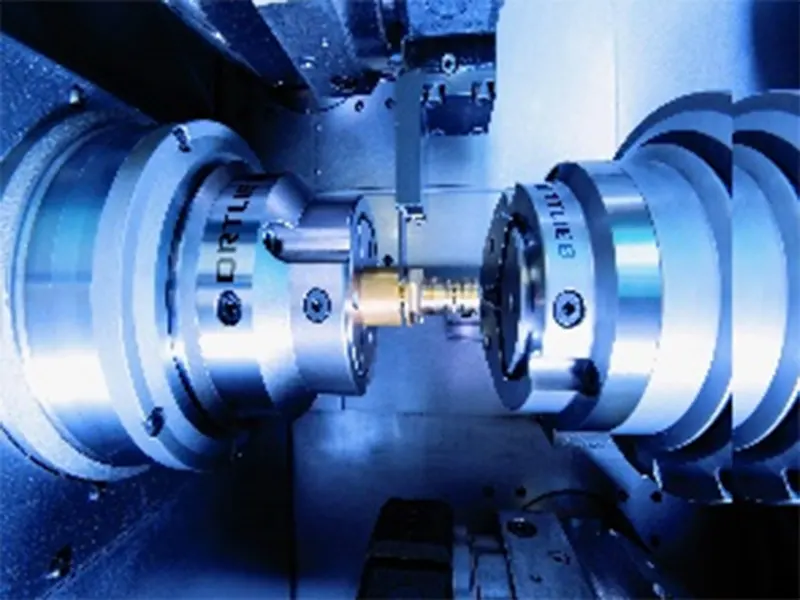

When should I choose CNC Machining Services?

Machined parts have the true properties of the material you select. Our process allows you to get parts machined from blocks of solid plastic and metal in the same time frame.

We mill and turn low quantities of parts very quickly. Typical quantities are one to 200 pieces and manufacturing times are 1 to 3 business days. We offer product developers parts machined from engineering-grade materials that are suitable for functional testing or end-use applications.

CNC machining is more expensive than plastic 3D printing, but it is the most feasible option for metal visual prototypes given the high cost of metal 3D printing and metal casting.

Company Strength

Related service

Inquire Now

Note:We will contact you within one working day. Please pay attention to your email.