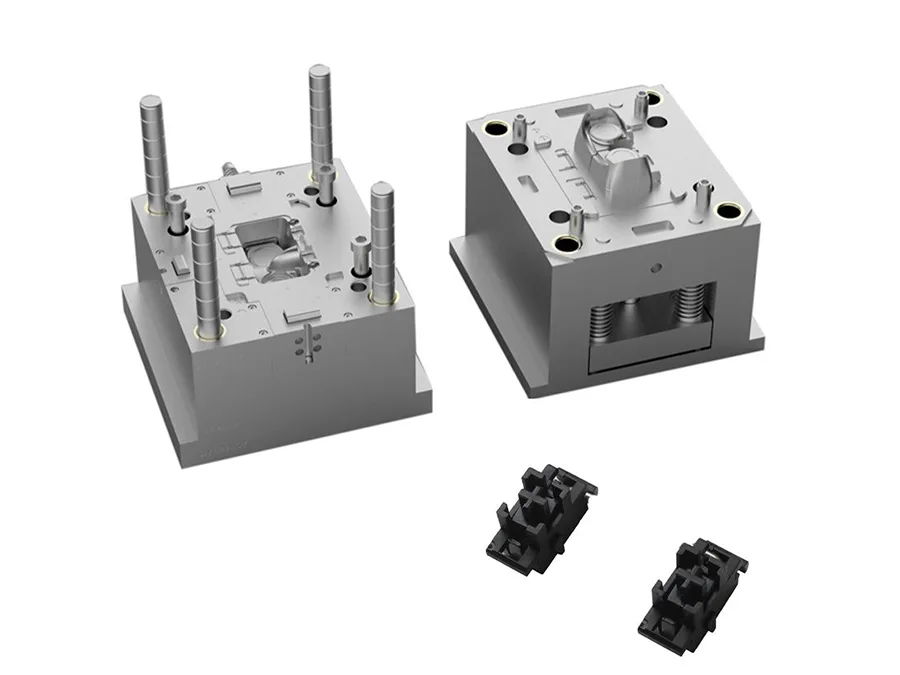

CNC-Machining Aluminum Molds

Use epoxy, polyester, or filled with metal, quartz sand and other reinforcements or low/medium melting point alloys to make simple structural molds.

Category:

Injection mould

key word:

Service Introduction

Mold manufacturing injection processing services

Use epoxy, polyester, or filled with metal, quartz sand and other reinforcements or low/medium melting point alloys to make simple structural molds. This type of mold has a simple manufacturing process, short cycle, and low price. It can only be produced in small and medium batches. Used for sample manufacturing.

Advantages of injection molding

Injection molding is a good choice for mass production of plastic parts.

After all, so many high-tech companies around the world use it to produce parts and components for a reason.

But what makes injection molding so popular?

1.High efficiency

The mold injection process is of highly efficience for small-batch prototyping service with the quantity of 500~5000PCS.

2.Excellent details

High-pressure injection ensures that the molten material reaches every gap in the mold before it solidifies. This allows design engineers to incorporate complex geometries and complex elements into their designs.

3.Cost-effective

Fast and efficient production ensures low cost of each part, while high production yields further economies of scale. Aluminum is a cost-effective, readily available material that can be used as a cost control tool.

4.Mass production

The use of steel molds for injection molding can facilitate the mass production of millions of parts.

5.High tensile strength

Adding fillers to the liquid resin can enhance the tensile strength of injection molded parts.

6.rapid prototyping

Through proper treatment, the injection molded parts have a smooth finish when they come out of the mold, and no further refinement is required.

FAQ

Can I order just one piece?

Yes, of course you can, there is no minimum quantity with GZ Prototyping, we will recommend you with the most suitable and effective manufacturing solutions based on your quantities.

Does GZ-precision insure delivered goods?

No, we do not insure deliveries. However, you are free to use your own insurance.

When should I choose Vacuum Casting Services?

Vacuum casting is a method for making high quality prototypes or low volumes of parts formed from inexpensive silicone molds. Copies made in this way show great surface detail and fidelity to the original pattern.

When should I choose 3D printing Services?

We can use diverse 3D printing processes to fabricate your parts. More rapid and cost-effective compared with CNC Machining from one piece to large quantities.

3D printing has become a standard technique for developing one-off visual prototypes due to its speed, affordability, and flexibility. Printed parts sometimes lack strength and impact resistance, but this matters little for visual prototypes.

When should I choose CNC Machining Services?

Machined parts have the true properties of the material you select. Our process allows you to get parts machined from blocks of solid plastic and metal in the same time frame.

We mill and turn low quantities of parts very quickly. Typical quantities are one to 200 pieces and manufacturing times are 1 to 3 business days. We offer product developers parts machined from engineering-grade materials that are suitable for functional testing or end-use applications.

CNC machining is more expensive than plastic 3D printing, but it is the most feasible option for metal visual prototypes given the high cost of metal 3D printing and metal casting.

Company Strength

Related service

Inquire Now

Note:We will contact you within one working day. Please pay attention to your email.