Vacuum casting

Vacuum casting is an effective way to manufacture low-volume production of functional prototypes and plastic parts, and helps you strike a balance between high-quality production parts and shortest lead times.

Category:

Service

key word:

Vacuum casting

Service Introduction

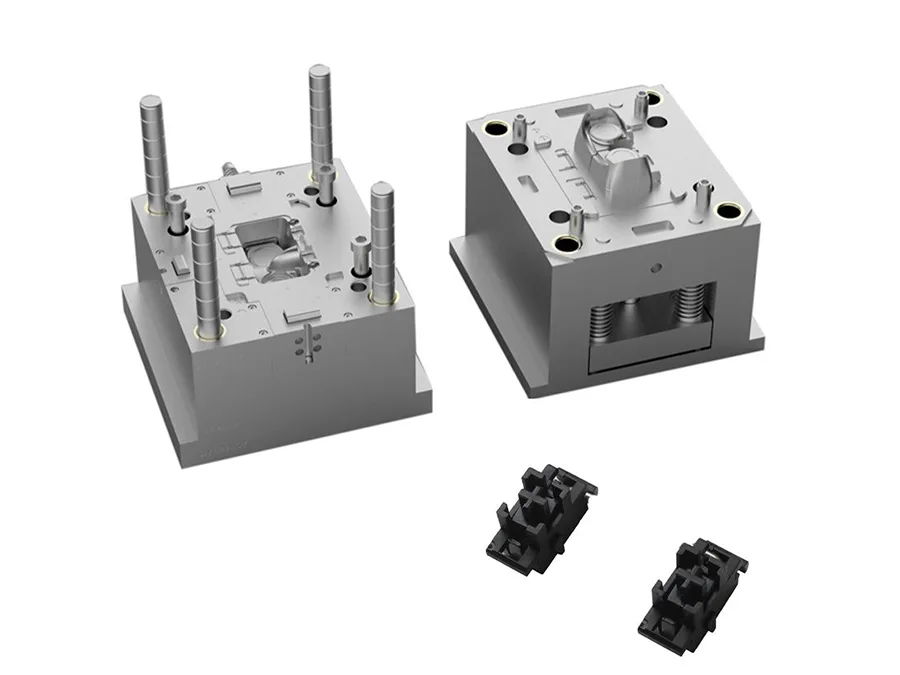

Vacuum casting (also known as polyurethane casting, silicone mold casting) is an economical alternative to small batch injection molding of plastic parts.

It can be used to simulate the final molded part or finished product. Generally speaking, the mold is made of silicone rubber and uses CNC or SLA part as a main mode.

These molds replicate details and textures and give a consistent finish from one part to the next.

Vacuum casting is an effective way to manufacture low-volume production of functional prototypes and plastic parts, and helps you strike a balance between high-quality production parts and shortest lead times.

Functional Prototypes:Can be used to produce high-quality functional prototypes for mechanical and structural testing that accurately simulate the appearance, color, and material of the final product.

Low-volume production: When quantity requirements are not enough to invest in injection molds, it can help you quickly customize low-volume production parts.

Market testing: Prototypes produced by vacuum casting can be used for market testing to obtain consumer feedback and optimize the product before mass production.

Models and displays: Models and displays for trade shows, product launches, and marketing campaigns with high-quality finishes and detailed features suitable for visual display.

Medical industry: used to create parts for custom medical devices, such as prostheses and medical models.

Electronic enclosures: e.g., rapid fabrication and evaluation of electronic product enclosures for mobile phones, laptops, wearables, etc.

Automotive industry: production of automotive interior and exterior trims, lamps and test components, etc.

Aerospace: Models and low-cost components of aircraft interior components.

Design verification: Designers can use vacuum casting to make high-quality samples for appearance and use verification before the final product is designed.

FAQ

Can I order just one piece?

Yes, of course you can, there is no minimum quantity with GZ Prototyping, we will recommend you with the most suitable and effective manufacturing solutions based on your quantities.

Does GZ-precision insure delivered goods?

No, we do not insure deliveries. However, you are free to use your own insurance.

When should I choose Vacuum Casting Services?

Vacuum casting is a method for making high quality prototypes or low volumes of parts formed from inexpensive silicone molds. Copies made in this way show great surface detail and fidelity to the original pattern.

When should I choose 3D printing Services?

We can use diverse 3D printing processes to fabricate your parts. More rapid and cost-effective compared with CNC Machining from one piece to large quantities.

3D printing has become a standard technique for developing one-off visual prototypes due to its speed, affordability, and flexibility. Printed parts sometimes lack strength and impact resistance, but this matters little for visual prototypes.

When should I choose CNC Machining Services?

Machined parts have the true properties of the material you select. Our process allows you to get parts machined from blocks of solid plastic and metal in the same time frame.

We mill and turn low quantities of parts very quickly. Typical quantities are one to 200 pieces and manufacturing times are 1 to 3 business days. We offer product developers parts machined from engineering-grade materials that are suitable for functional testing or end-use applications.

CNC machining is more expensive than plastic 3D printing, but it is the most feasible option for metal visual prototypes given the high cost of metal 3D printing and metal casting.

Company Strength

Related service

Inquire Now

Note:We will contact you within one working day. Please pay attention to your email.